viaDuct-3D Factory

Efficient production starts in the office

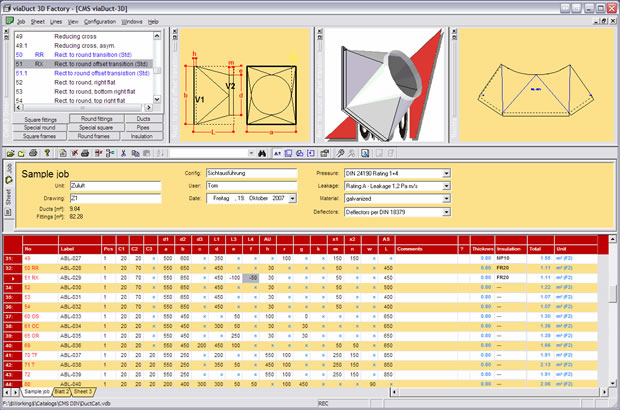

And this is where our application software viaDuct-3D excels: it was developed especially for the HVAC requirements and while powerful and versatile, it still easy and intuitive to operate. viaDuct-3D controls the entire production process, from processing your customer's orders via e-mail or manual data entry in simple list form, through generating all CAD data files for all your shop's machines for producing the order, and finally invoicing and tracking the customers payments.

In viaDuct-3D data is stored in a database and organized into customers and sheets. Data is entered into an Excel-like table, whereby only the important parts measurements need to be entered by the operator. All other data, e.g. seams, allowances, notches, are automatically appended according to production rules, that you can specify, allowing even inexperienced office workers to enter jobs. Optimally, any of the defaults settings can be overridden and even cutouts can be inserted into any side a part. During data entry, the parts are automatically redrawn and displayed in 2D, 3D and even the unfolded shapes are shown with allowances, notches depicted. The lists can be edited, copied and deleted, much the same way as in other Windows programs. Entire jobs can be imported and exported in many common formats and various managers allow overview of orders, jobs and invoices at all times. Furthermore, your customers can enter their jobs themselves using viaDuct-3D Customer and transmit their orders directly to you for manufacturing.

After a job has been entered, you start processing by pressing a single function key and all parts are unfolded, nested and the required CAD files for your production machines, e.g. plasma cutters (plasmaWASP as well as other machines), duct formers, shears or our varioFormer, are generated according to the rules you have specified.

|

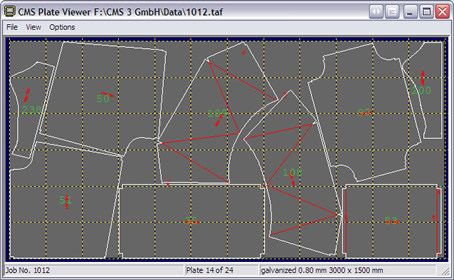

Parts to be cut on a plasma cutter are nested with our unique optimizing nesting program OptiNest, which further improves the nesting result by several percent. YOu can choose between fast rectangular nesting, when time is important, or complete, optimized nesting if you need the best nesting result.

viaDuct-3D automatically generates the CAD commands to utilize the marking pen feature of our plasma cutters. Thereby you can select to have important information e.g. part labels, folding angles, written on the parts and folding lines can be marked as well, which greatly simplifies further processing of these parts.

The integrated report generator allows configuring any type of report that may even include graphics and barcodes. |

viaDuct-3D is absolutely unparalleled in its configureability: all 2D/3D drawings and the unfolded parts, as well as all formulas and checks are written in the integrated scripting language and can easily be modified, or new parts can be created an added to the existing standard library. An elaborate online help system, with numerous examples, makes utilizing this BASIC-like language easy to use. (Click here to view the viaDuct-3D help. Internet connection necessary.)

Maintenance of our software is done using update files sent by e-mail, which can perform any type a change to your local installation, or using our help desk feature, which allows remote control of your system from anywhere in the world.

viaDuct-3D runs under any Windows operating system and is currently available in 8 languages: German, English, French, Flemish, Spanish, Polish, Tchech and Russian. - next - |